When using SAP S/4HANA to complete warehouse management activities, you can perform goods receipt for external procurement, production receipt, internal stock transfer, and customer returns.

In this blog post, we’ll discuss goods receipt from external procurement and production receipt, both from a business process and systems point of view.

Business Process

If you’re receiving goods from an external vendor, the goods receipt process may vary depending on whether you’re using an advanced shipping notice (ASN). Whether you require an ASN from the vendor is controlled by setting the confirmation control key at the purchase order item level. If the confirmation control key is set, then you need to create an inbound delivery to complete goods receipts in embedded EWM.

Based on the MRP run, you decide to go ahead with the creation of a planned order or purchase requisition. You can create the purchase order manually or convert the purchase requisition to form a purchase order. The purchase order is sent to the supplier, and the supplier can either physically send the goods or send an advanced shipping notice (ASN) to confirm when the goods will arrive in the warehouse. The receipt of an ASN creates the inbound delivery in SAP S/4HANA.

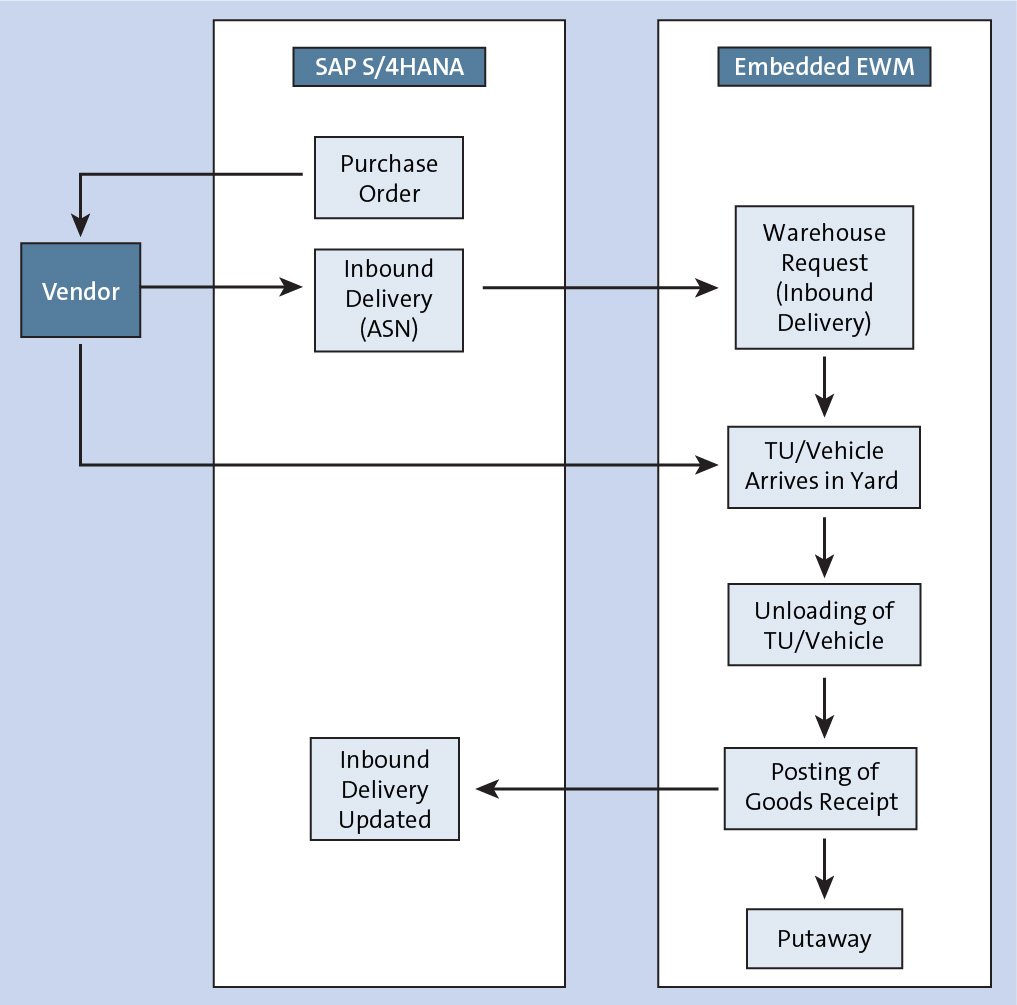

If you’re working with ASNs, the inbound process in embedded EWM begins with the receipt of an ASN sent from the vendor and the creation of an inbound delivery in SAP. The SAP S/4HANA system is the leading system for creation of purchase orders and inbound deliveries. The complete process of goods receipt and putaway is then carried out in embedded EWM. You can post the goods receipt when the goods physically arrive in the warehouse.

When an ASN is created, the system checks for the plant and storage location in the ASN and validates if the corresponding warehouse for that plant and storage location is managed by embedded EWM. If it is, then the system distributes the inbound delivery to embedded EWM and creates the inbound delivery. This is done by calling a qRFC-enabled function module. This document becomes the warehouse request in embedded EWM for goods receipt management and putaway.

The following figure summarizes how the inbound delivery document is created in embedded EWM using an ASN in SAP S/4HANA.

Users with prior experience working with decentralized SAP EWM will notice that an inbound delivery notification is no longer created in SAP S/4HANA. This is one of the simplification strategies in embedded EWM.

Once the inbound delivery is created, you can progress to the next steps in the inbound process, which may include the following:

- Arrival of vehicle or TU in the yard

- Unloading of TU for delivery

- Posting of goods receipt

- Putaway of products/handling units (HUs)

Creation of an expected goods receipt document for goods receipt isn’t required in embedded EWM in SAP S/4HANA. The inbound delivery gets information directly from the purchase/manufacturing order in SAP S/4HANA.

The inbound process in embedded EWM also can be used to receive finished goods in the warehouse. Depending on settings in SAP S/4HANA, you can trigger goods receipt posting directly from SAP S/4HANA or from embedded EWM.

You can trigger goods receipt posting directly from SAP S/4HANA by using the inbound delivery created in SAP S/4HANA as soon as you’ve executed the last step in the production or process order. The inbound delivery is created in embedded EWM only if the receiving plant and storage location are embedded EWM-managed.

The finished products are moved into the warehouse from the assembly line and goods receipt is posted in embedded EWM. The same is also updated in the inbound delivery in SAP S/4HANA. You then create warehouse tasks for putaway and complete the putaway in embedded EWM.

Example

Let’s consider a domestic company for a moment. It sends an order to one of its vendors based in another country. The order sent contains various products that are to be delivered to them in a timely manner. A purchase representative keys in the order in SAP S/4HANA, and, based on material requirements, creates an inbound delivery in SAP S/4HANA that contains the products to be supplied as part of a single delivery.

As shown in the figure below, after the inbound delivery is saved in SAP S/4HANA, it flows through to embedded EWM and is saved as an inbound delivery order. After the goods are received in the goods receipt area of the warehouse, goods receipt is posted in the staging area of the warehouse. Goods may also be flagged for quality inspection if quality management (QM) is activated for the product. After the checks and any ongoing packaging requirements, the goods are put away by the warehouse worker in the final putaway area based on the destination bin that the embedded EWM system proposes. The warehouse workers usually get putaway warehouse tasks on their Process Warehouse Tasks – Putaway app or the RF device they use to work in the warehouse.

System Process

The following explains the basic system flow, including the documents and the data required to execute putaway of stock from the inbound door to the destination bin in embedded EWM and decentralized EWM. Briefly, each step in the inbound process is as follows:

- The inbound process starts with the creation of an inbound delivery in SAP S/4HANA. The inbound delivery can be created from various business processes:

- Purchase: A purchase order is created in SAP S/4HANA that requires putaway of goods from an embedded EWM-managed warehouse.

- Customer returns: A customer returns order can be created in SAP S/4HANA that requires putaway of goods to an embedded EWM-managed plant for the goods returning from the customer location.

- Production staging: A manufacturing order is created for receiving finished materials for production in the production staging area. These goods are put away to a destination bin based on the product putaway characteristics.

- An inbound delivery is created in SAP S/4HANA for putaway to the embedded EWM warehouse. The inbound delivery can be created for any of the scenarios described in the previous step. The inbound delivery contains all the relevant data required for stock putaway: product, quantity, batch, and so on.

- The inbound delivery is replicated to embedded EWM, and an inbound delivery is created in embedded EWM. This document serves as the requirements document in embedded EWM and is called the warehouse request. Further processing in embedded EWM such as staging, packing, and putaway is done based on the inbound delivery via creation of warehouse tasks.

- After the warehouse worker finishes the stock putaway, and all associated warehouse tasks are confirmed, the embedded EWM system posts the goods receipt. The goods receipt is also updated in the inbound delivery in SAP S/4HANA.

- The use of a TU is optional in embedded EWM. However, organizations can activate shipping and receiving functions in embedded EWM and make use of TU and vehicle activities to execute carrying of goods in the warehouse and unloading them. The stock is moved to a staging area after TU docks to the door and then is unloaded from a TU. Goods receipt can be posted after putaway is complete, which results in posting of goods receipt in the outbound delivery in SAP S/4HANA.

Storage Control

Storage control is used in a complex putaway process, in which a product must move through various process steps based on warehouse processes or the physical layout of the warehouse before it’s moved to the destination storage bin.

There are two types of storage control in embedded EWM:

- Process-oriented storage control

- Layout-oriented storage control

Process-oriented storage control is used for executing process steps based on warehouse processes. Some of the warehouse processes include quality inspection, value-added services (VAS), deconsolidation, and kitting. Layout-oriented storage control is used to execute warehouse processes based on warehouse layout.

For example, a product might need to be moved to the first floor in the warehouse to reach the final putaway bin via an elevator. In this case, the putaway storage process will have two process steps. The first step will move the product from the staging area to the elevator, and the second process will move the product from the elevator to the door.

The purpose of this storage control is to have stock visibility at all times in the warehouse. If a product must undergo both process-oriented and layout-oriented storage control, embedded EWM gives preference to process-oriented storage control.

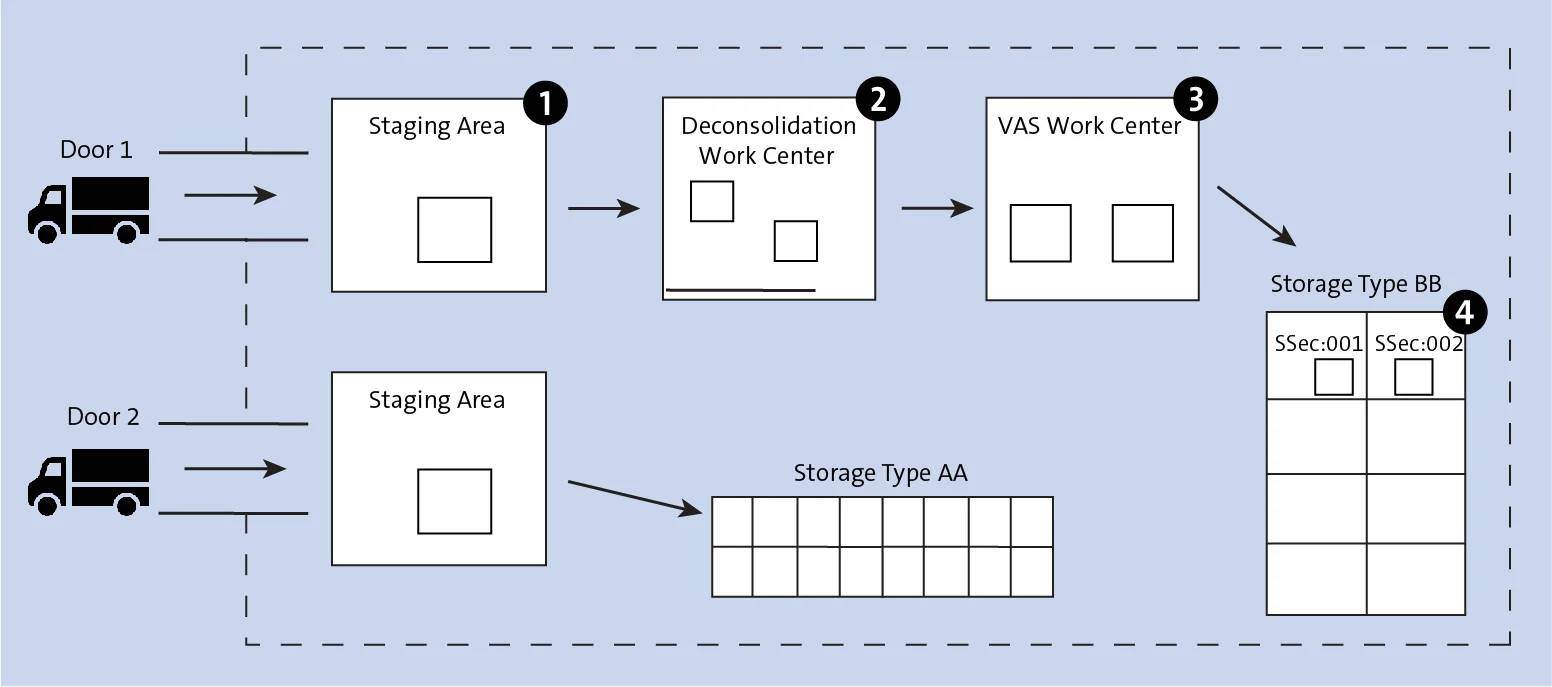

The figure below shows complex movement in the inbound process using only process-oriented storage control.

The primary steps involved in complex putaway are as follows, but note that they can include further steps (counting, quality inspection, etc.):

- Unloading (1): After the truck docks at the warehouse door, it’s unloaded using an HU warehouse task.

- Deconsolidation (2): The pallets are taken to a deconsolidation work center, where they’re broken down to move individual products to their destination.

- Value additions (3): Based on relevance for VAS, embedded EWM creates an HU warehouse task to move the product to a VAS work center. VAS activities performed at the VAS work center include activities like painting, oiling, packaging, and so on.

- Putaway (4): A final putaway HU warehouse task is now created or activated to move product from the VAS work center to destination storage bins. You can confirm the warehouse task from SAP GUI or using an RF device.

Conclusion

Now that you have a better understanding of the basic inbound process in embedded EWM in SAP S/4HANA’s logistics functionality, you should be able to keep up with the management process without wondering what’s going on. Of course, real experience is an important way of learning, too—so keep this information in the back of your mind as you go out and work in the warehouse.

This content was originally posted on the SAP PRESS Blog and has been adapted from a section of the book Warehouse Management with SAP S/4HANA by Namita Sachan and Aman Jain. Used with permission of SAP PRESS. All rights reserved.