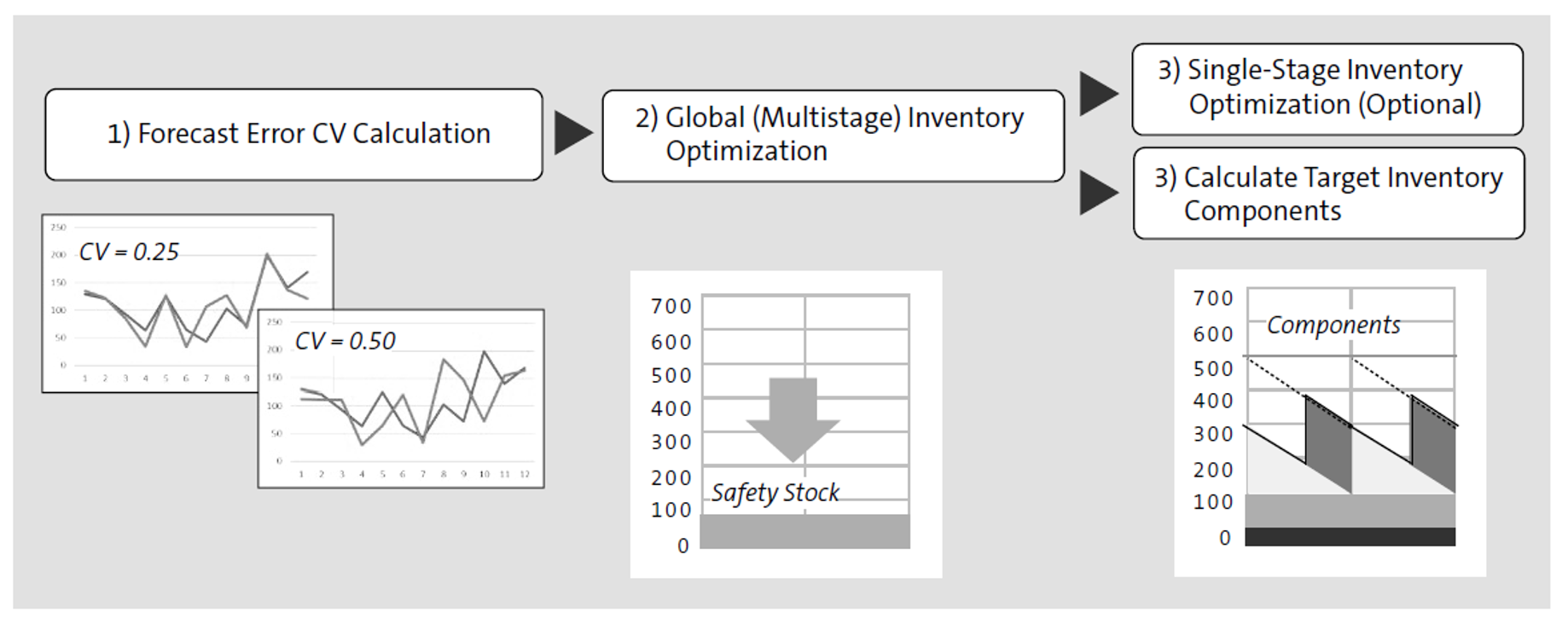

To calculate safety stock with SAP Integrated Business Planning for inventory, some operations must be executed in sequence.

Check out the figure below. First and foremost, the forecast error in SAP IBP is calculated, which will act as an input in the global multistage inventory optimization process. Once the safety stock for finished products is calculated from global multistage optimization, then the last step is to calculate the target inventory for the required components.

Let’s walk through this sequence in more detail.

Calculate Forecast Error CV Operator

This operator calculates the forecast error CV and other error measures from the historical demand forecast and the actual historical demand. These outputs can serve as key inputs to the global (multistage) inventory optimization operator, which has the following capabilities:

- Calculates values for the scope defined by planning filters or Microsoft Excel view filters

- Allows for flexible operator settings to adjust the forecast error CV

- Enables you to specify a past time horizon over which CV will be calculated

- Inputs planning levels at which CV will be calculated

- Uses the sales order as an input key figure and the CV as an output key figure

- Allows adjustments in calculation method (MAD versus MAPE), in forecast bias, in outlier detection, and more

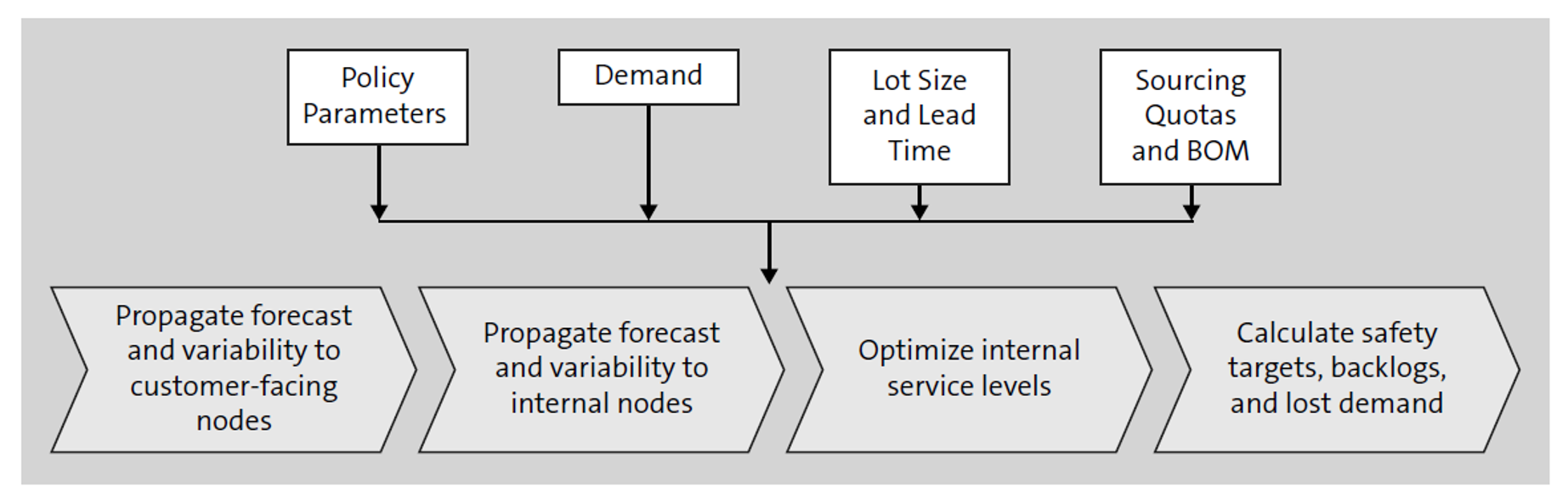

Global (Multistage) Inventory Optimization Operator

This operator will optimize safety stock globally and simultaneously across all products and locations in your supply chain while considering demand uncertainty, supply uncertainty, supply quantities, lead times, costs, and service levels. The figure below shows the flow for a multistage inventory optimization process, which has the following capabilities:

- Propagates forecast and forecast variability to internal (upstream) nodes of a supply chain network

- Propagates forecast and forecast variability to stocking nodes that have customer demand

- Optimizes internal service levels between internal (upstream) nodes of your supply chain network

- Calculates safety stock targets, backorders, and average expedited quantities

- Calculates values for your whole supply chain network

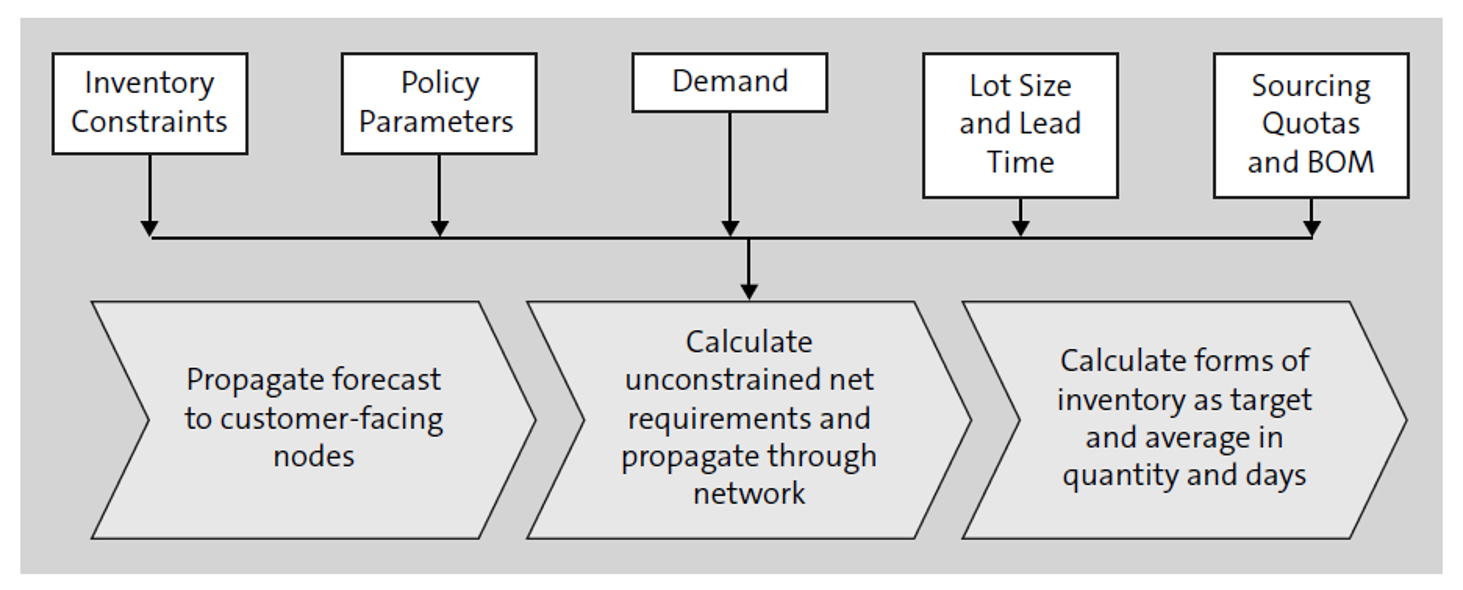

Calculate Target Inventory Components Operator

This operator will calculate target inventory components, as shown below. Recommended safety stock, cycle stock, and pipeline stock are various component of target inventory. This operator has the following capabilities:

- Runs a calculation with respect to optimal inventory targets

- Estimates targets, average quantities and currency values of the inventory position, on-hand stock, cycle stock, pipeline stock, and merchandising stock

- Supports minimum stock requirements and cost per unit as inputs

- Calculates the reorder point and the days of supply for recommended safety stock and for on-hand stock (target, average, and end of period)

- Calculates values for the entire network

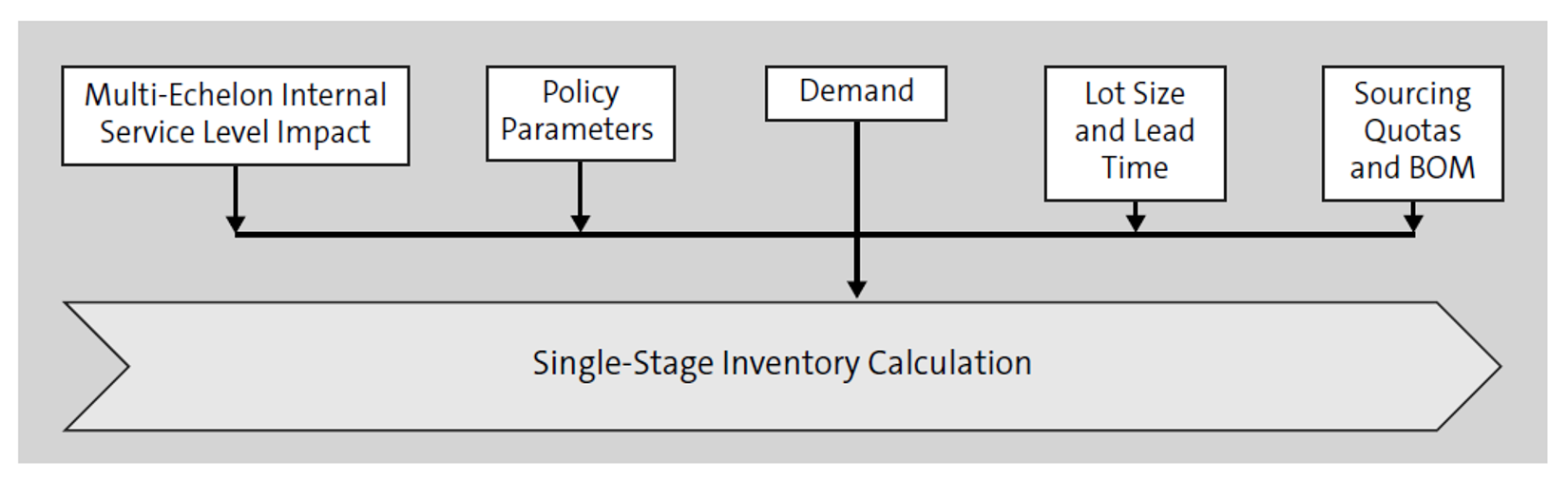

Decomposed (Single-Stage) Inventory Optimization Operator

In certain cases, you want to see the impact of multistage inventory optimization with changes in inputs at a certain location. To handle such a requirement, the single-stage inventory optimization operator can be executed, which will recommend the safety stock only for the executed location without the taking variability of the entire supply chain into account. The final figure below shows the single-stage optimization process flow, which has the following capabilities:

- Ideal for running simulations where you want to determine the impact on recommended safety stock for local changes to input key figures

- Optimizes recommended safety stock locally for any combination of product and location

- Requires a successful run of the global multistage inventory optimization operator

- Calculates values for a scope defined by the planning filters or Microsoft Excel view filters

- Additionally useful for producing missing data when you have an individual customer-facing node of the supply chain with incomplete inventory data

This content was originally posted on the SAP PRESS Blog and has been adapted from a section of the book SAP IBP for Supply Chain Certification Guide: Application Associate Exam by Parag Bakde and Rishabh Gupta. Used with permission of SAP PRESS. All rights reserved.